A little after the lunch stop, the sky turned dark, the wind picked up and it began to snow. Before long, the track was hard to find - even obliterated in places. Sometimes, you were skiing by trying to feel for the tracks (something I have had experience of before).

Towards the end, my skis started to ice up. The first time, I just scraped the ice off the skintec kick zone. Later on, the whole skis felt leaden and stuck to the ground. Checking the skis, even the glide zone was sticking. So to make the last couple of kilometers, drastic measures were called for. Knowing that I have a brand new set of the two stripe skintec modules (carried with me now, after yesterday's incident), and that these have some mileage on the clock (400km), I decided to experiment, and after clearing the snow and as much of the ice as I could, put a layer of liquid glide wax from end to end of the skis, including on the skintec grip zone. The skis were completely transformed, not only gliding well, but also the kick performing well. It was good to get good glide and predictable behaviour Just in time, as the final part of the day is to use the drag lift to get to the centre on the top of the mountain.

This provided some useful learning.

- I did not expect the glide zone to ice up. But if faced with these conditions again after skiing some distance, I will be quicker to brush on some liquid glide wax.

- I will track down some proper anti-icing for the waxless skis. But in the meantime, I now know that liquid glide wax is at least a potential problem solver in extreme conditions.

- In these extreme conditions, it makes sense to periodically check the skintec modules for icing. Also, test out if anti-icing will keep the keyhole free of ice to be able to quickly change modules.

I will have to investigate other means of de-icing - will some of these thermal hand warmers provide a means of thawing them out? If the air temperature is above zero, then swapping the modules out with spares from time to time would allow the modules not in contact with the tracks to thaw out.

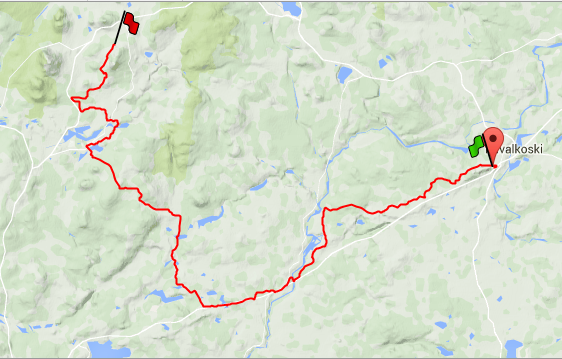

Here is today's route:

Here is today's route:

No comments:

Post a Comment